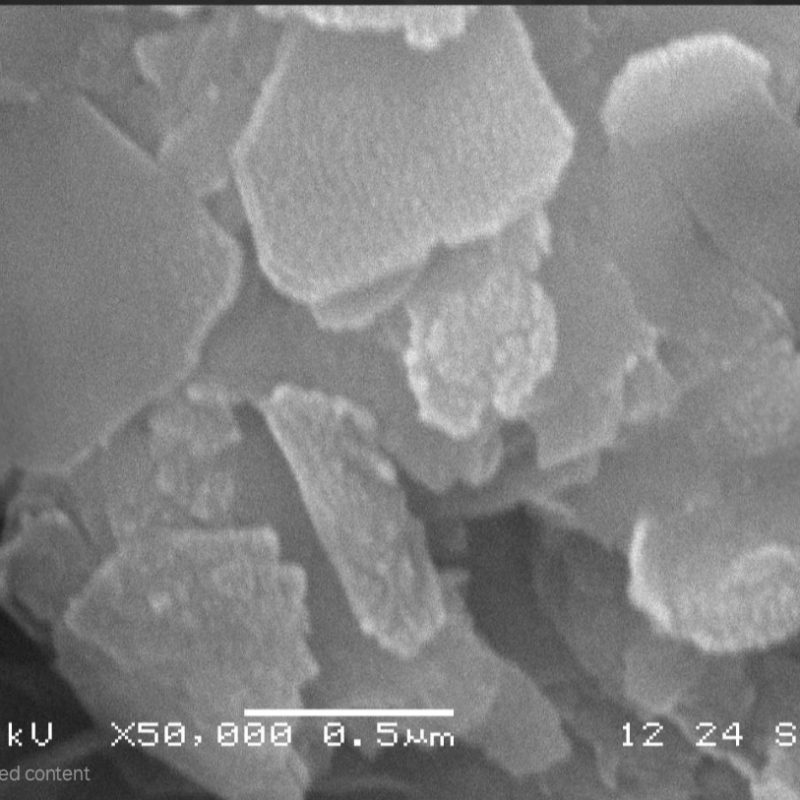

Tungsten Disulfide (WS2) is one of the most advanced and effective dry/solid lubricants available today. Known for its ultra-low friction properties, WS2 offers a coefficient of friction as low as 0.03 (dynamic) and 0.07 (static)—lower than that of Graphite or Molybdenum Disulfide (MoS2). This makes it one of the most lubricious substances in the world.

Exceptional Performance Under Extreme Conditions

WS2 performs exceptionally well in extreme environments, making it a go-to choice for high-demand applications:

WS2 vs MoS2 : A Step Above

Although both WS2 and MoS2 are transition metal dichalcogenides, WS₂ offers several advantages:

Because of these qualities, WS2 can be used as a more advanced alternative to MoS2 in many critical applications.

Versatile Applications Across Industries

The unique combination of low friction, high temperature tolerance, and extreme pressure resistance makes WS2 suitable for a wide range of uses, including:

Innovative Potential

Thanks to its unmatched dry lubricity, WS2 opens up possibilities for experimentation and innovation across industries. Whether it’s applied to mechanical parts, high-performance coatings, or cutting-edge devices, its versatility and reliability make it an excellent solution for almost any lubrication challenge.

WS2 continues to attract interest in advanced fields like nanoelectronics, coatings, and energy storage, thanks to its unique combination of mechanical strength, chemical stability, and tribological performance.

(USES) / Applications of Tungsten Disulfide (WS2) Powder

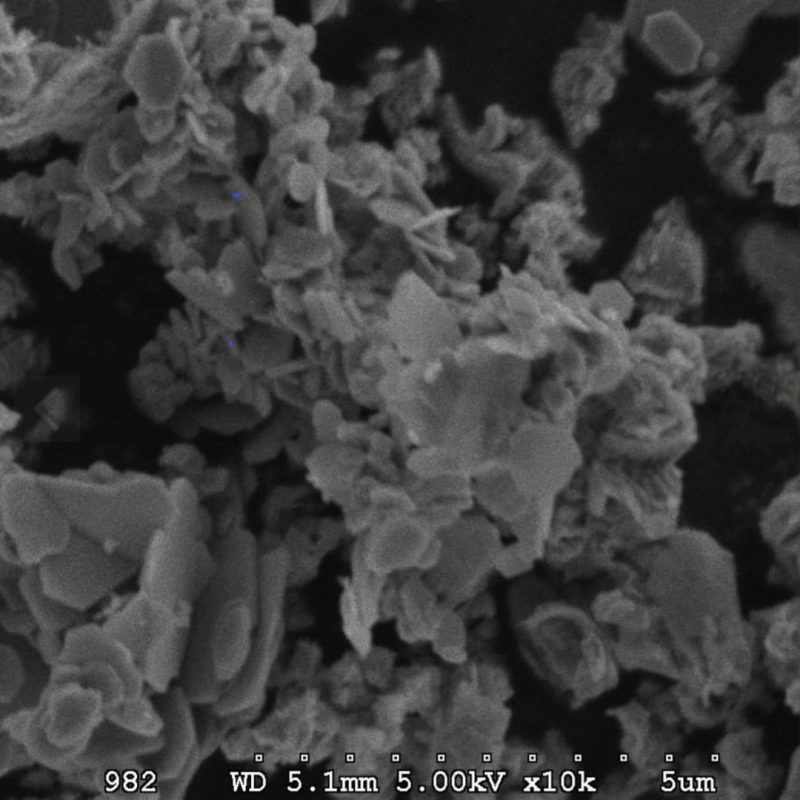

Tungsten Disulfide (WS2) powder is a high-performance dry lubricant used across a wide range of industries. It can be applied either as an additive to oils and greases or as a standalone dry coating, offering exceptional friction reduction, thermal stability, and wear resistance.

WS2 powder can be applied directly to surfaces that require long-lasting, dry lubrication—without the need for binders or complex processing.

WS2 powder can also be used as a performance-enhancing additive in wet lubricants:

Due to its unique structure and properties, WS2 powder is also gaining interest in high-tech and research fields.

Industries Benefiting from WS2 Powder

Conclusion

Whether used as a dry film coating or an additive to conventional lubricants, WS2 powder delivers outstanding tribological performance. Its ability to withstand extreme temperatures and loads makes it an ideal solution for critical applications across automotive, aerospace, marine, and industrial sectors.

Jade Chemicals specializes in high-performance lubricants engineered to reduce friction and wear in demanding applications.

© Copyright 2025 by jadechemicals.in