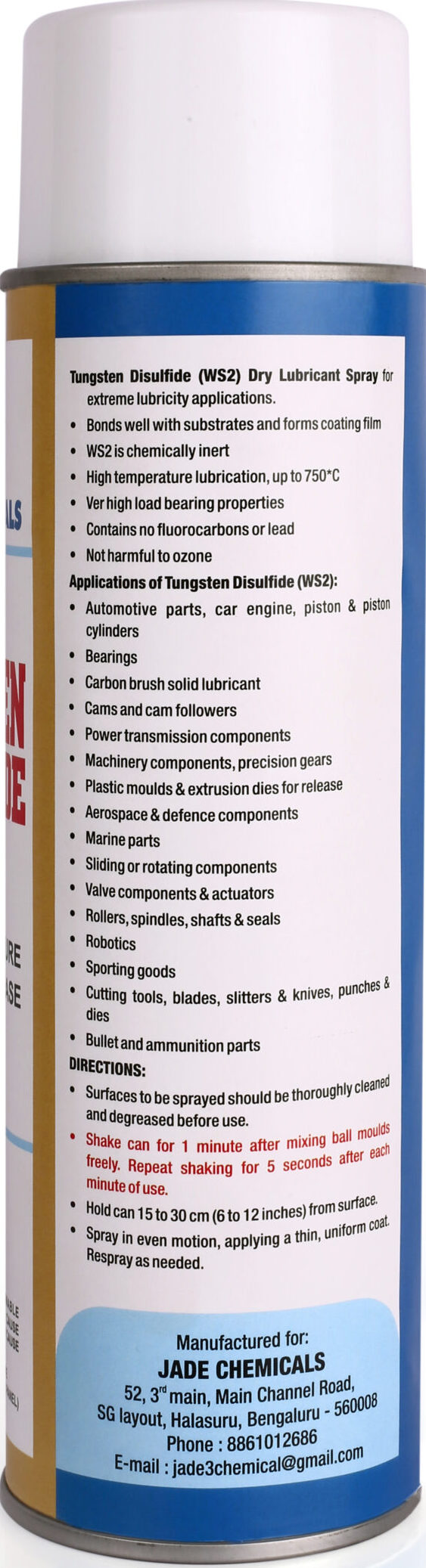

Tungsten Disulfide (WS2) aerosol spray is an efficient solution for applying a thin, even lubricating film in hard-to-reach areas or on complex surfaces. It comes in easy-to-use (370 gms) spray cans, ideal for both maintenance and industrial applications.

Key Benefits and Features:

Typical Applications:

Aerospace, automotive, mold release, high-performance machinery, and precision tools — anywhere a dry, clean, high-load lubricant is required.

Used for lubricating high-performance components such as turbine blades, bearings, and fasteners where high load capacity and thermal stability are critical.

Applied to engine parts, gears, pistons, and chassis components to reduce friction, enhance wear resistance, and improve performance under extreme pressure.

Acts as a dry release agent in plastic and rubber molding processes, especially where conventional lubricants are not suitable due to temperature or surface sensitivity.

Ideal for lubricating delicate or inaccessible mechanical parts such as hinges, slides, and micro-mechanisms where a clean, dry lubricant is preferred.

Used to extend the life of high-load gears, chains, and bearings in machinery that operates under harsh environments or intermittent lubrication conditions.

Applied as a lubricant in cold forming, stamping, and drawing operations where extreme pressure and clean operation are required.

Utilized in weapons, targeting systems, and communication equipment to ensure smooth operation without attracting dust or grit.

Offers lubrication without conductivity, making it safe for use on connectors and components where electrical isolation is important.

Protects components from corrosion, salt spray, and high load conditions, especially where conventional lubricants may fail.

Used on robotic joints, actuators, and linear guides to ensure smooth, quiet, and efficient motion in high-precision applications.

These applications leverage WS2 aerosol spray’s key strengths: extreme pressure resistance, thermal stability, chemical inertness, and the ability to form a clean, dry lubricating film on a wide range of surfaces.

Uses of Tungsten Disulfide (WS2) Spray